Selecting the right doming machine for your production needs requires evaluating several key factors. Below is a step-by-step guide to help you determine the most suitable model and configuration.

Label Style Confirmation

The first step is to confirm the layout style of your labels, as this directly determines the machine configuration and production efficiency. Are they regularly arranged or randomly placed?

Regular / Simple Labels (Neatly Arranged in Rows)

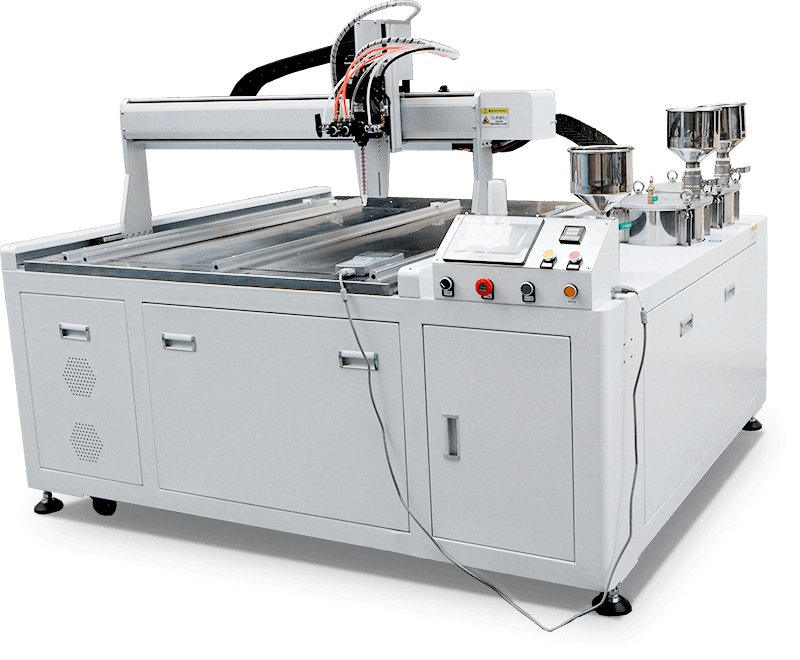

- Ideal for our standard 👉 DJ771-3 Axis Automatic Doming Machine

- Can be equipped with a multi-head dispensing module, allowing glue to be dispensed on multiple labels at the same time. This greatly improves efficiency for large-volume, repetitive production.

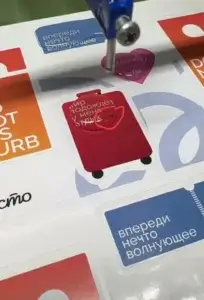

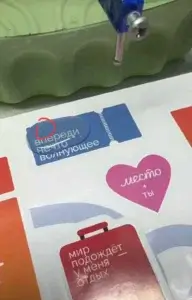

Irregular / Complex Labels (Randomly Placed, Varying Shapes & Sizes)

- On standard machines, programming the dispensing path is very time-consuming for complex labels. Labels must also be placed in fixed positions, and even small deviations can cause defects.

- For these cases, we recommend our 👉 SJ4060 CCD Auto-Positioning Doming Machine

- Equipped with a CCD camera vision system, this model automatically detects and locates each label’s position and outline, ensuring accurate dispensing without the need for precise manual placement.

Glue Type and Composition

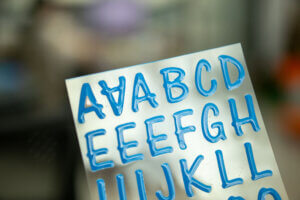

The choice of resin directly affects the doming process and final product quality. The two most common options are Epoxy Resin and Polyurethane (PU) Resin.

Epoxy Resin (Mixing Ratio 3:1)

- Operating / Pot Life: ~50 minutes at 25℃, allowing sufficient working time.

- Curing Time: 10–12 hours for initial curing, ~18 hours for full curing at room temperature.

- Properties: High transparency, smooth finish, natural bubble release, good flexibility.

- Durability: UV resistant but limited anti-yellowing—typically 6–12 months before noticeable yellowing.

- Best for: General doming applications where cost efficiency is key and UV exposure is limited.

Polyurethane (PU Resin, Mixing Ratio 1:1)

- Operating / Pot Life: ~15 minutes at 25℃, requiring quick operation.

- Curing Time: ~24 hours at room temperature; 2–4 hours with heating at 60–65℃.

- Properties: High transparency, glossy finish, smooth surface without ripples, excellent bubble elimination.

- Durability: Outstanding UV and weather resistance; maintains clarity for 12+ months.

- Best for: Premium applications requiring long-term durability, clarity, and anti-yellowing performance.

Comparison Table Between Epoxy and PU

| Feature | Epoxy Resin | Polyurethane (PU Resin) |

|---|---|---|

| Mixing Ratio | 3:1 | 1:1 |

| Pot Life (25℃) | ~50 min (longer, easier handling) | ~15 min (shorter, requires fast operation) |

| Curing Time | 10–18 hrs at room temp | 24 hrs at room temp / 2–4 hrs with heat |

| Transparency & Finish | High transparency, smooth surface | Very high transparency, glossy, ripple-free |

| Bubble Elimination | Natural deaeration, moderate | Excellent, especially with vacuum degassing |

| Anti-Yellowing | Moderate (6–12 months) | Excellent (12+ months) |

| Durability | Good, but weaker against UV | Strong UV/weather resistance |

| Cost | Lower (cost-effective) | Higher (premium choice) |

| Best For | Standard doming, cost-sensitive projects | High-end doming, long-lasting applications |

If you are using PU glue, we strongly recommend equipping the glue tank with a vacuum degassing function. This helps eliminate trapped air bubbles in the adhesive, ensuring smooth dispensing and preventing bubbles from forming inside the finished 3D stickers.

💡 Tip: If you can provide the TDS (Technical Data Sheet) of your adhesive, it will help us match the most suitable configuration. If not, we can recommend and supply compatible adhesives.

Applicable configurations:

- Gear pump/Screw pump

- Glue tank with mixing function

- Glue tank with vacuum degassing (recommended for PU glue)

Heating Function for Tank and Hoses

Please confirm whether heating is required for the glue tanks and hoses.

In cold environments, the viscosity of the adhesive increases significantly, which reduces its flowability and makes stable dispensing difficult. For this reason, in regions with low winter temperatures (e.g., Scandinavia, Russia), we recommend adding a heating function to maintain proper glue fluidity and ensure consistent production quality.

Applicable configuration:

- Glue tank with heating function

Effective Working Area

Please confirm the working area (travel range) you require. Selecting the right size ensures the doming machine can fully cover your label sheets and improve production efficiency.

DJ771 Standard Travel:

- 700 × 700 × 100 mm (X, Y, Z)

- Customizable travel available, up to 1200 × 1000 × 100 mm (X, Y, Z) for larger label formats

SJ4060 Largest Travel:

- 400 × 600 × 100 mm (X, Y, Z)

- Dual-table design for continuous operation and higher throughput

Why Choose Us? Take Action Now!

At Robota Dispensing, we don’t just provide machines—we deliver complete solutions for your sticker doming production.

🌟 Free Sampling Service: Simply send us your design file, and we’ll produce a sample for you. We can also recommend and supply the most suitable adhesive for your application.

👉 Contact us today and see how our professional doming machines can help you achieve high efficiency, stable quality, and cost savings in your production!