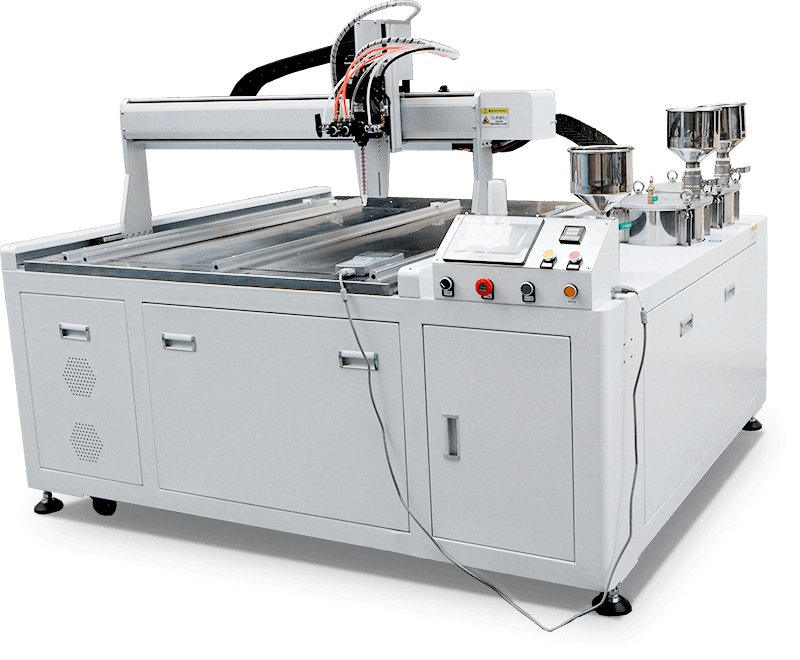

Automatic Sticker Resin Doming Machine for 3D Epoxy/Polyurethane Labels

Perfect for producing custom stickers, nameplates, badges, logos, keychains, crafts, promotional items and decorative products with clear, glass-like resin coating. Reliable, cost-effective and easy to use for small to large-scale production.

Products

Find The Right Solution

Small-Scale Solution

Medium-Scale Solution

Large-Scale Solution

Consumables

Latest Projects

Turn Your Challenges Into Real Solutions

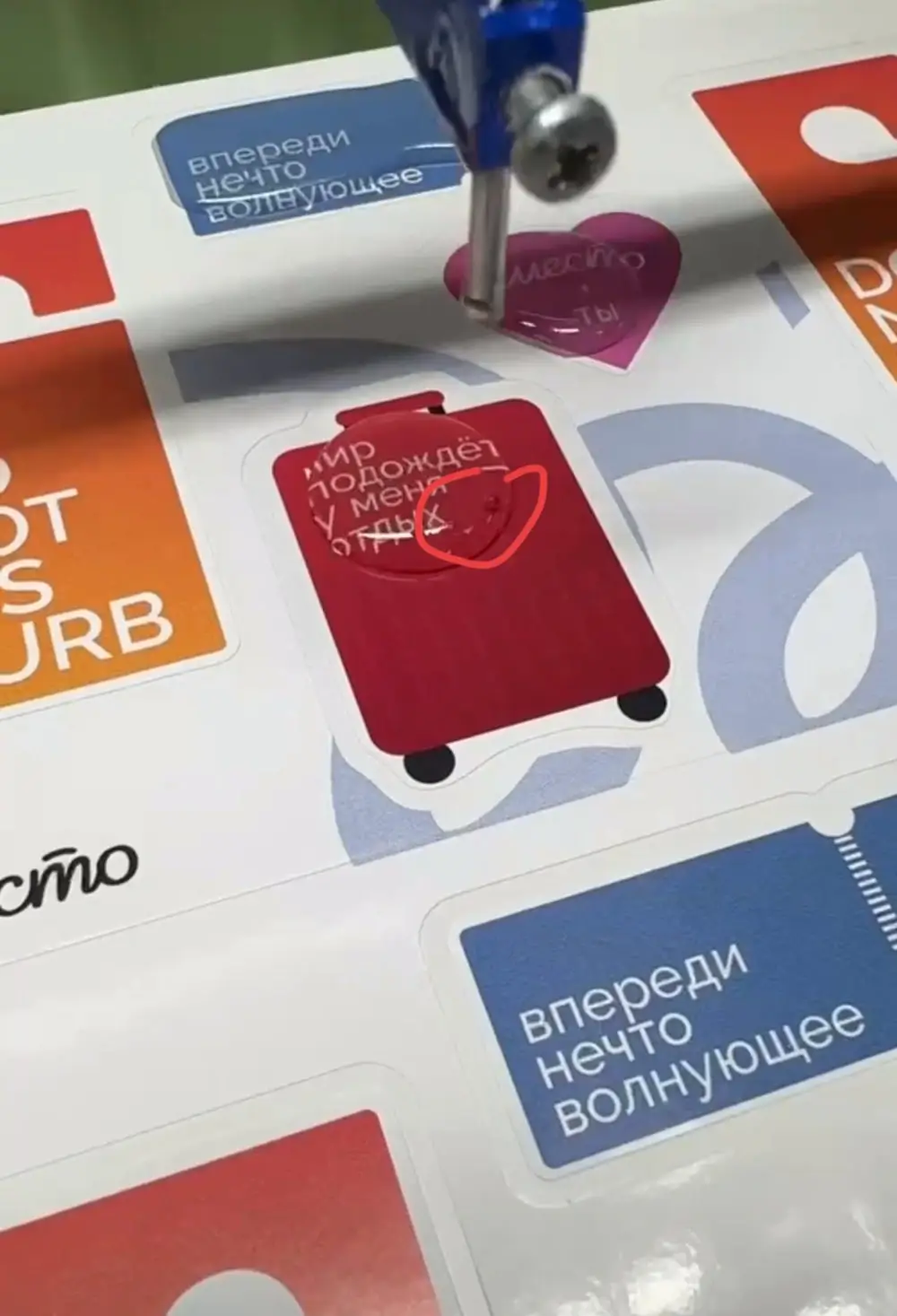

Complex Design Sticker

Company Nameplate

Simple Circle Sticker

WHY CHOOSE US

We Are More Than Just Equipment Suppliers

We specialize in high-quality sticker doming machines, engineered for ease of use with advanced PLC control and intelligent operation. Backed by strong R&D, our machines deliver innovative, reliable, and durable performance—perfect for producing glass-like stickers with simple or complex designs.

But we don’t stop at equipment. We also supply the complete range of raw materials needed for doming production, including epoxy resin, polyurethane, PVC films, and curing ovens. By combining machinery with consumables, we provide a true one-stop doming solution, helping advertising companies and manufacturers save time, reduce costs, and deliver stunning results.

2,000+m2

6 Hours

15+ Years

18 Months

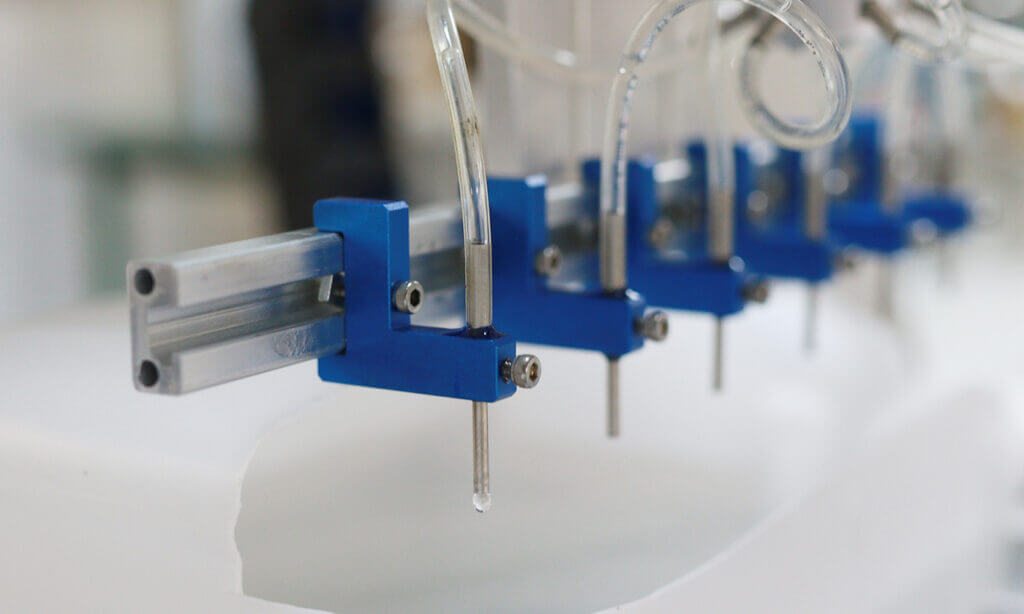

01. Air Bubbles in Stickers

Air trapped during resin dispensing causes visible bubbles, ruining surface clarity and product quality, leading to high rejection rates and rework.

02. Uncured or Sticky Resin

Robota’s engineering team delivers a doming machine specifically optimized for cold environments. The one-button heating system stabilizes resin temperature, ensuring proper curing, consistent hardness, and a flawless glossy finish.

03. Inconsistent Dome Height

Manual dispensing or unstable equipment often produces uneven dome thickness, affecting product uniformity and professional appearance.

04. Slow Production Speed

Manual or semi-automatic processes limit output, making it hard to meet bulk order deadlines and increasing overall production costs.

05. High Material Waste

Inaccurate dispensing and overflow during doming waste expensive resin materials and raise operational expenses.

06. Operator Fatigue & Inaccuracy

Long manual operations lead to operator fatigue, inconsistency, and lower precision, especially for complex or high-volume sticker batches.

Subscribe for a Free Demo Now

Blog

Learn More With Us

How to Choose the Right Robota Sticker Doming Machine

Why Can Polyurethane, PVC, and Silicone Serve as Adhesives, Plastics, Rubbers, or Leather?

Methods for Removing Electronic Potting Compound

01. Sample Information Collection and Equipment Matching

Customers need to provide specific product/sticker dimensions/material (e.g., PVC/metal). We recommend suitable machines (desktop/industrial) within 24h, including size/power specs.

02. Adhesive Performance Verification and Equipment Adaptation

Submit adhesive TDS/brand. Our team will analyze the adhesive properties within 3 business days and issue a compatibility report. If special configurations are required, we will detail the modification plan and costs. This step ensures hardware compatibility with the adhesive to prevent production issues.

03. Effect-Oriented Adhesive Recommendations

For customers who have not yet finalized an adhesive, we will request their core requirements (e.g., “high transparency,” “flexible bend resistance,”). We will provide a recommended adhesive, including key parameters (viscosity, curing time, yellowing resistance), cost ranges, and application scenarios. This helps customers balance performance and budget.

04. Free Sample Testing and Parameter Optimization

Customers may send 10-20 sticker sheet samples and 10-20kg adhesive, which we will test within 7 business days. We will return the samples with a Report (detailing dispensing speed, curing temperature, etc.) and provide high-resolution photos or videos of the results. Remote video consultations are available for adjustments to dome height or edge smoothness.

05. Equipment Production and Process Parameter Finalization

After sample approval, standard equipment will be produced within 15 days, while customized models will take approximately 25-35 days. Weekly progress updates will be shared. Final process parameters will be preloaded into the equipment control system before delivery, enabling “plug-and-play” functionality.

06. Equipment Delivery and Operational Training

Customized operation videos will be provided (covering startup/shutdown procedures, maintenance tips, and troubleshooting) with English subtitles and timestamped key steps. Post-delivery support includes 12 months of free technical consultation.