Polyurethane/Epoxy Resin for 3D Sticker

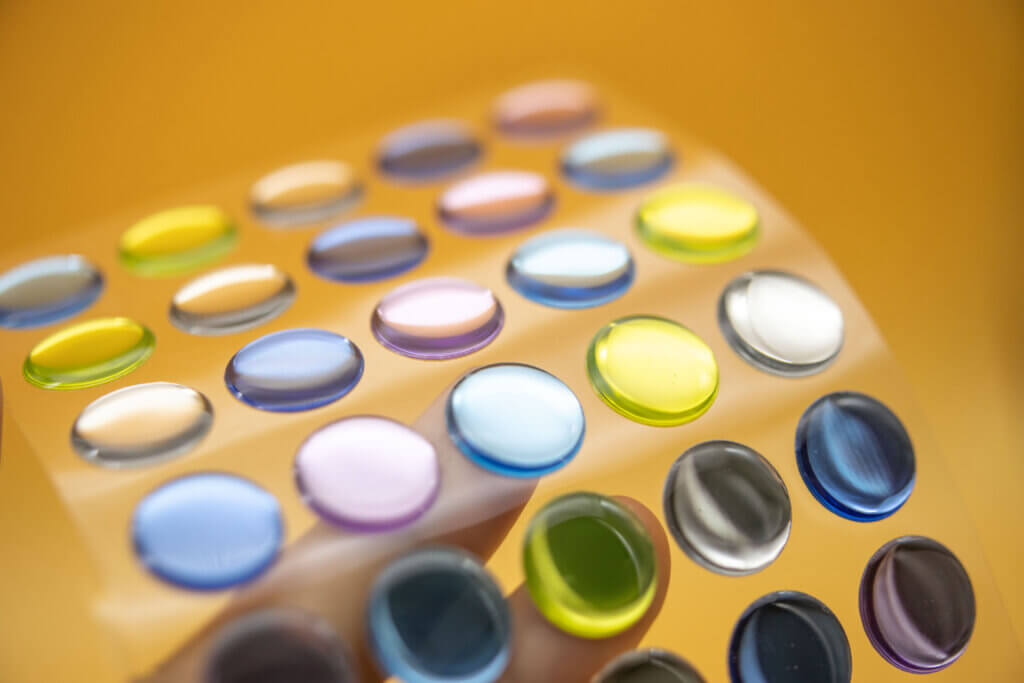

Polyurethane Resin for 3D Domed Sticker/Label

3:1 Soft Epoxy Resin for 3D Domed Sticker/Label

Suitable Products

How to Apply

01. Measure & Mix

02. Degas (if needed)

03. Apply

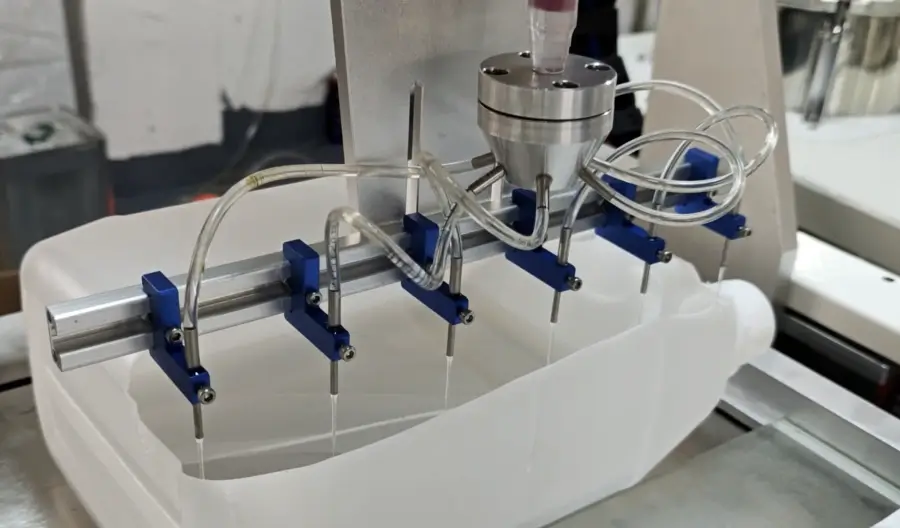

01. Load & Preheat

02. Purge & Test

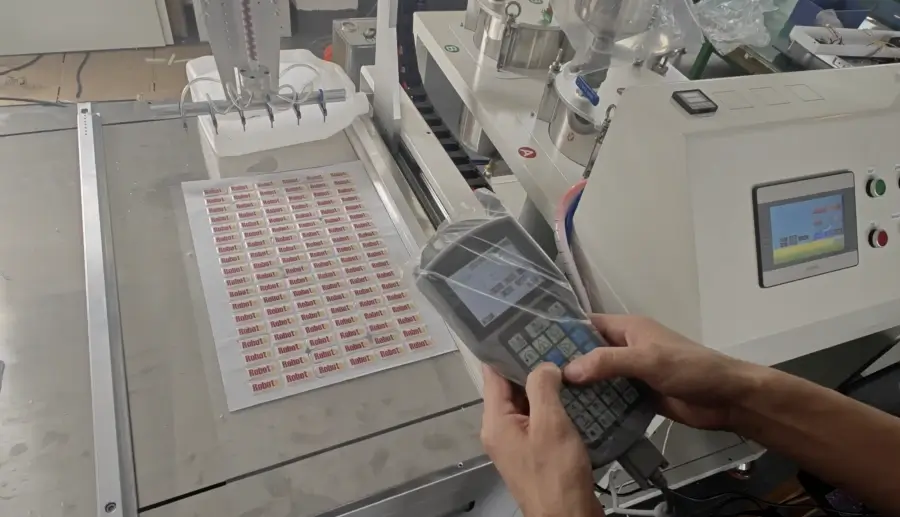

03. Program & Run

Latest Projects

Turn Your Challenges Into Real Solutions

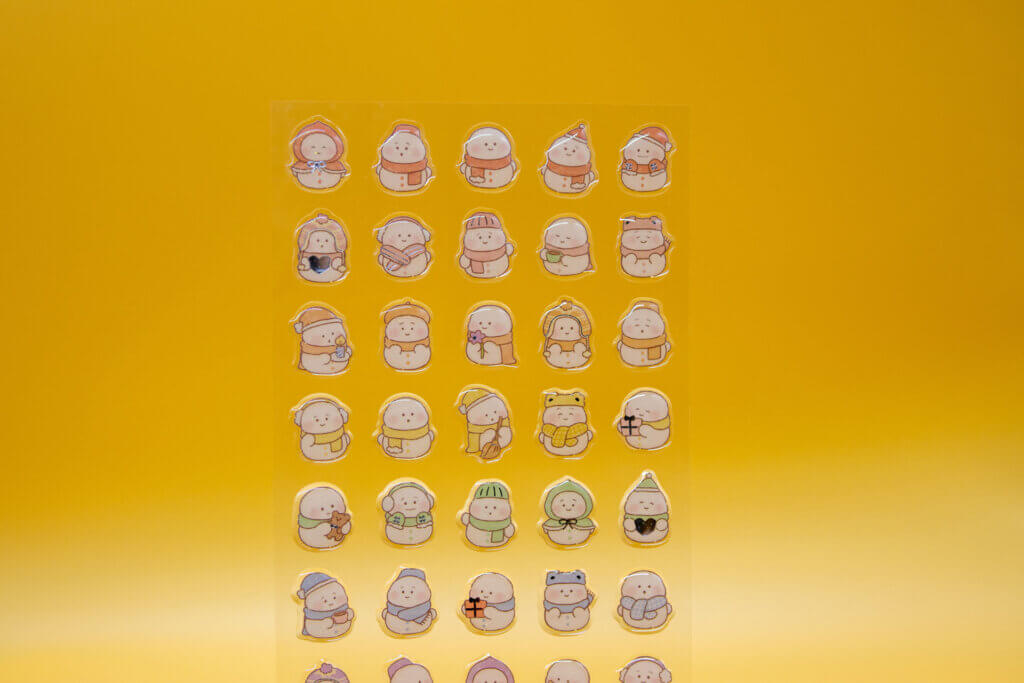

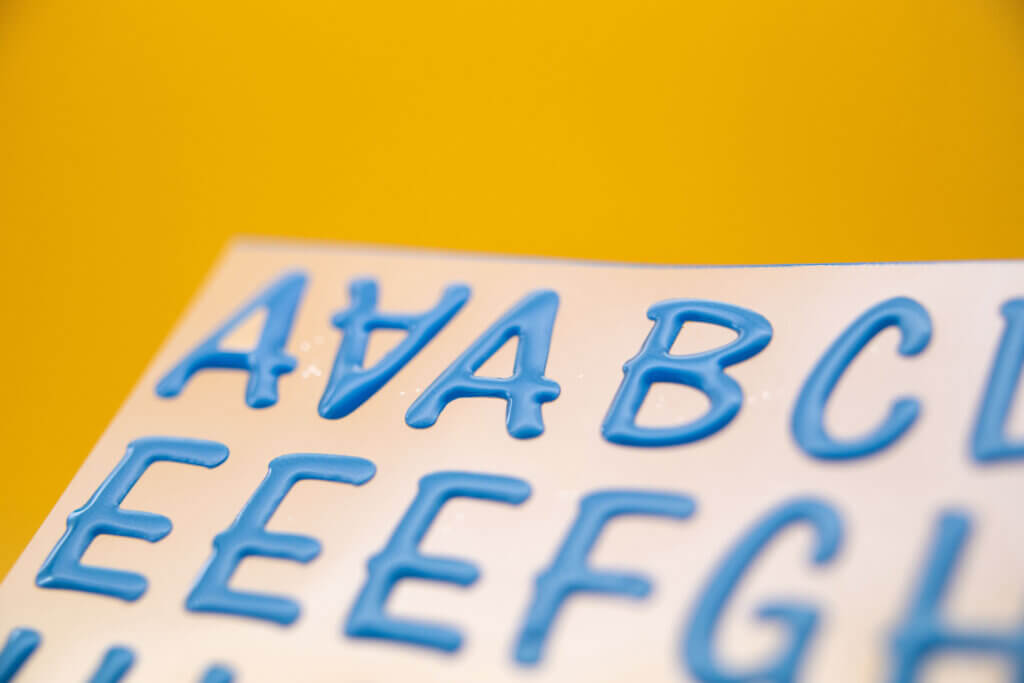

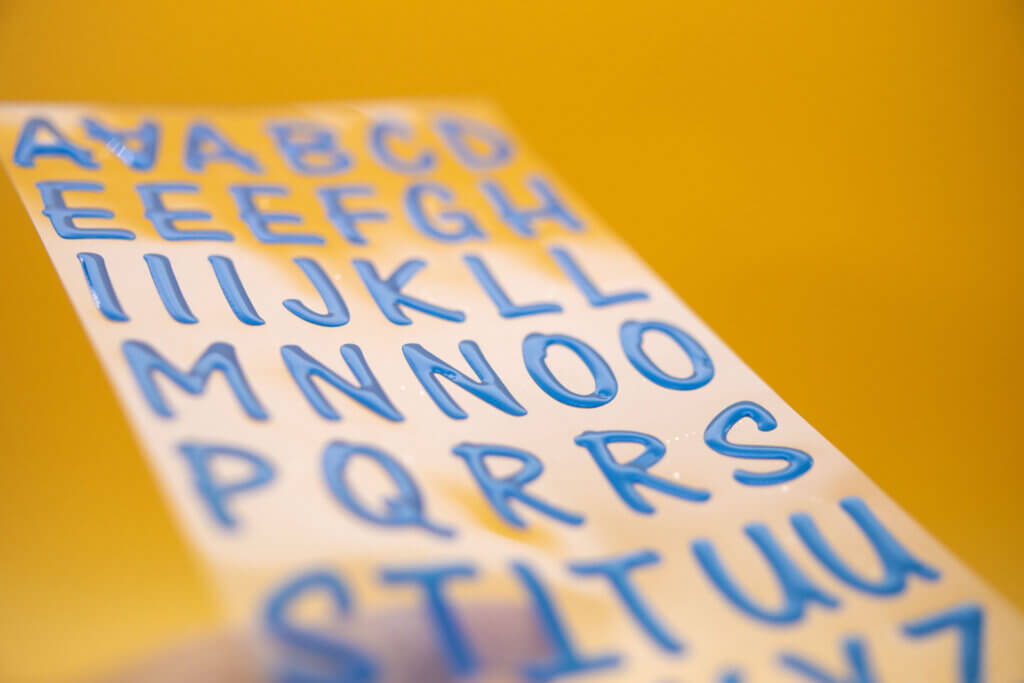

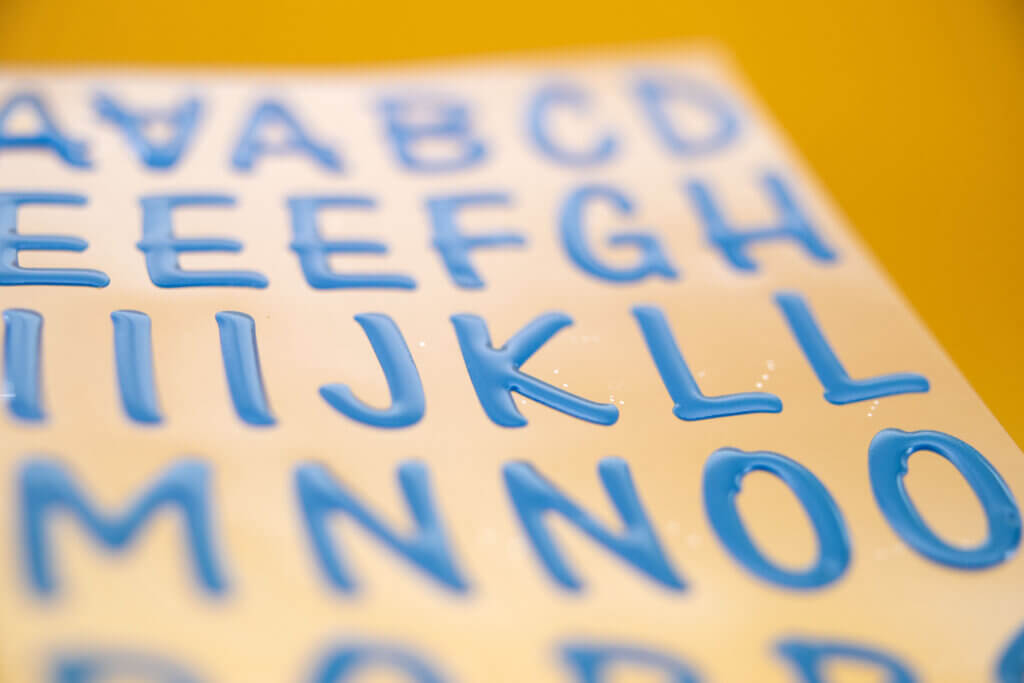

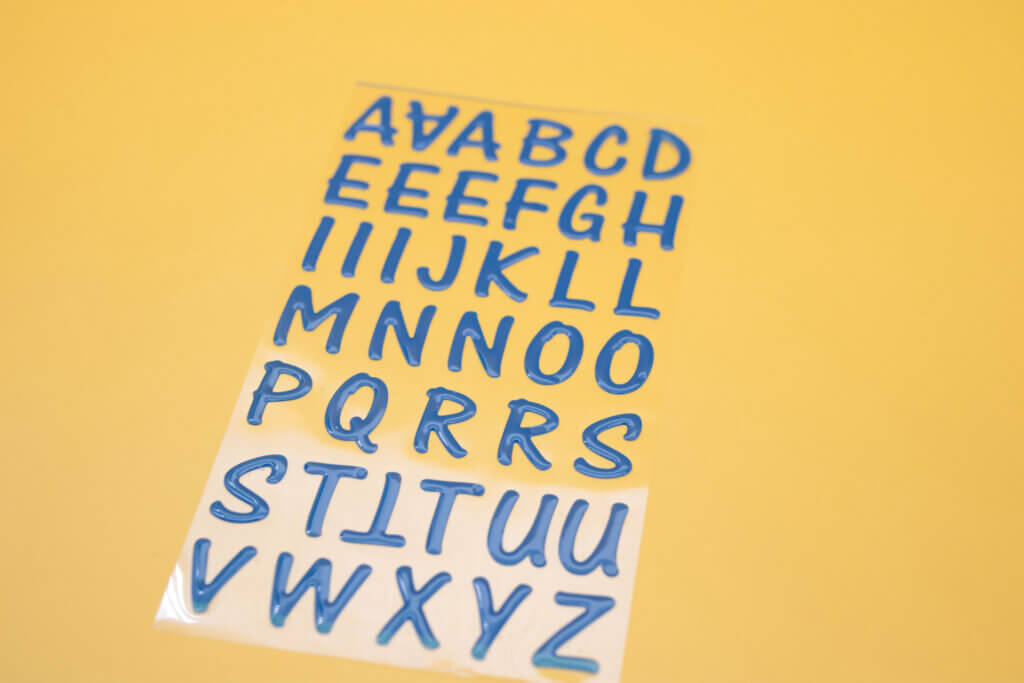

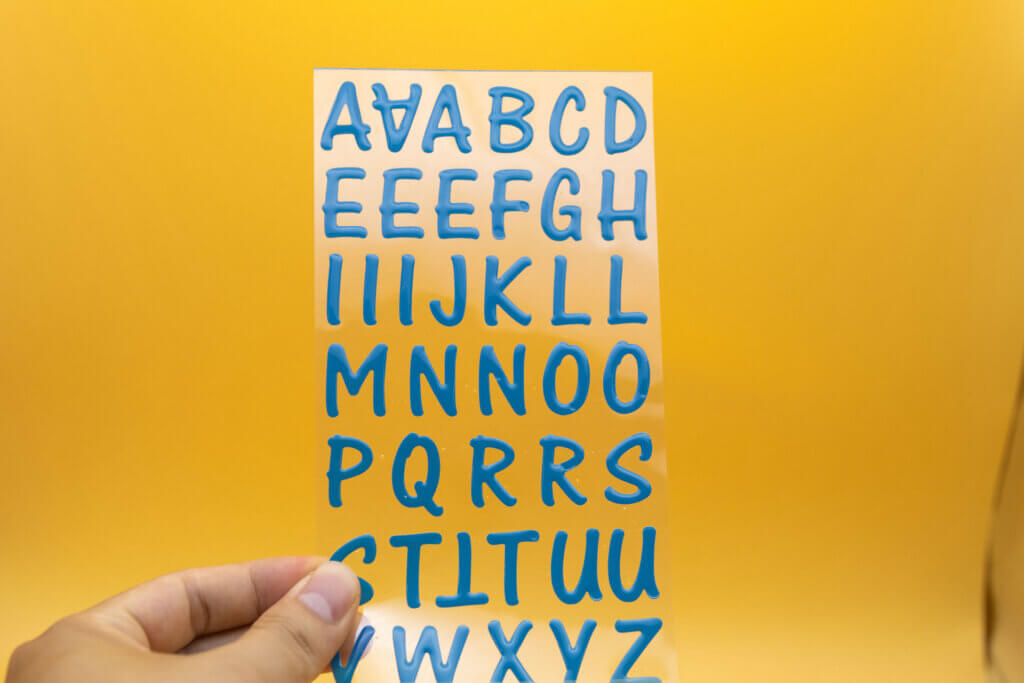

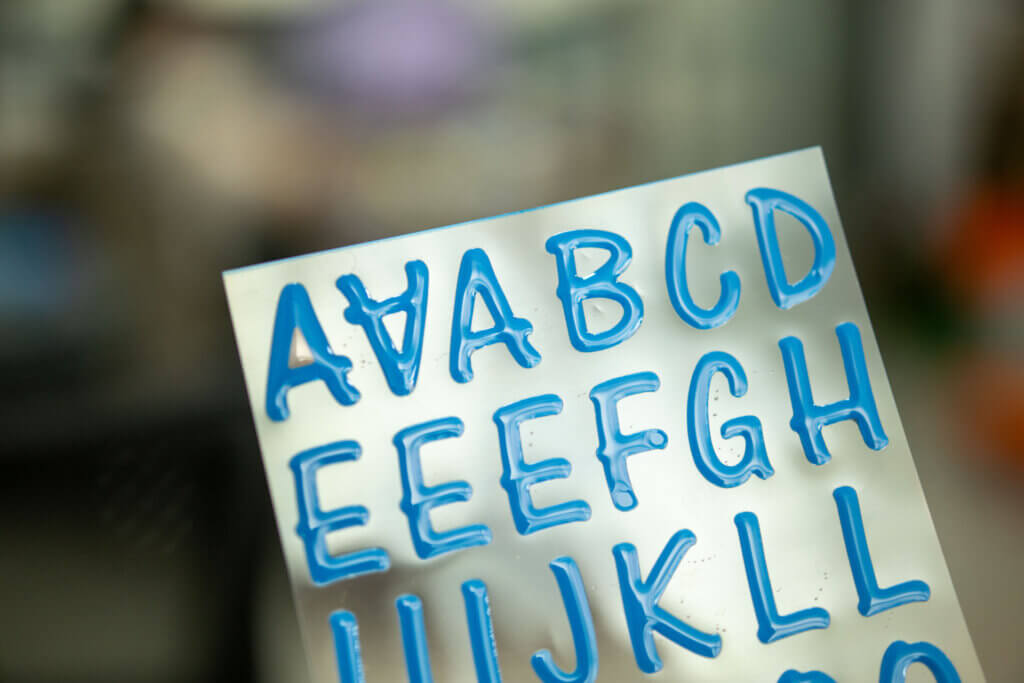

Complex Design Sticker

Tiny PET Toy Sticker

Simple Circle Sticker

Epoxy Resin Handling & Storage FAQs

Q1: What are the basic safety requirements for the operating environment?

-

Ensure proper ventilation (install exhaust systems or keep windows/doors open).

-

Maintain a 3-meter distance from ignition sources (welding, sparks, open flames).

-

Use chemical-resistant mats and equip the area with fire extinguishers (dry powder/CO₂).

-

Q2: What to do if resin contacts the eyes?

-

Immediate action: Rinse eyes continuously with an eyewash station or clean water for 15 minutes, holding eyelids open.

-

Medical attention: Visit an ophthalmologist even if symptoms subside (bring the product’s MSDS sheet).

-

Avoid: Rubbing eyes or using chemical neutralizers.

-

Q3: How to handle skin contact with uncured resin?

-

Initial response:

-

Wipe off excess resin with gloves and clean paper/cloth.

-

Clean residue using a propylene glycol methyl ether-based cleaner.

-

-

Deep cleaning:

-

Wash thoroughly with warm soapy water for 2+ minutes.

-

Use olive oil to soften stubborn residue before rinsing.

-

-

Medical care: Apply hydrocortisone cream for redness/burning and seek medical help if irritation persists.

-

Q4: Why is pre-application testing mandatory?

-

Material validation: Verify adhesion to substrates (e.g., PVC/metal) via crosshatch adhesion test (≥4B rating).

-

Process calibration: Adjust mixing ratios and curing conditions (temperature tolerance: ±2°C).

-

Risk mitigation: Prevent batch defects (e.g., surface whitening) due to humidity >70%.

-

Q5: How to manage opened resin containers?

-

Sealing protocol:

-

Purge containers with nitrogen gas and seal with aluminum foil + PE film.

-

Use opened resin within 72 hours.

-

-

Quality checks:

-

Cloudy/Crystallized Part A: Reheat to 40°C (104°F) and stir.

-

Overly viscous Part B: Discard immediately.

-

-

Q6: What are the optimal storage conditions for unopened resin?

-

Environment:

-

Temperature: 15-25°C (59-77°F) with <±3°C daily fluctuation.

-

Humidity: <60% RH (use desiccant cabinets).

-

Light protection: Store in original amber containers (no transparent packaging).

-

-

Handling:

-

Stack containers >15 cm (6 in) above ground and >50 cm (20 in) from walls.

-

Use shock-absorbing pads for multi-layer storage.

-

-

Q7: How to dispose of resin waste safely?

-

Uncured waste:

-

Classify as HW13 hazardous waste (organic solvents) and store in leak-proof containers.

-

Dispose via licensed incineration facilities.

-

-

Cured waste:

-

Crush into non-hazardous construction filler materials (requires local environmental permits).

-

Never landfill or pour into drains.

-

-

Product

Find The Right Solution

Small-Scale Solution

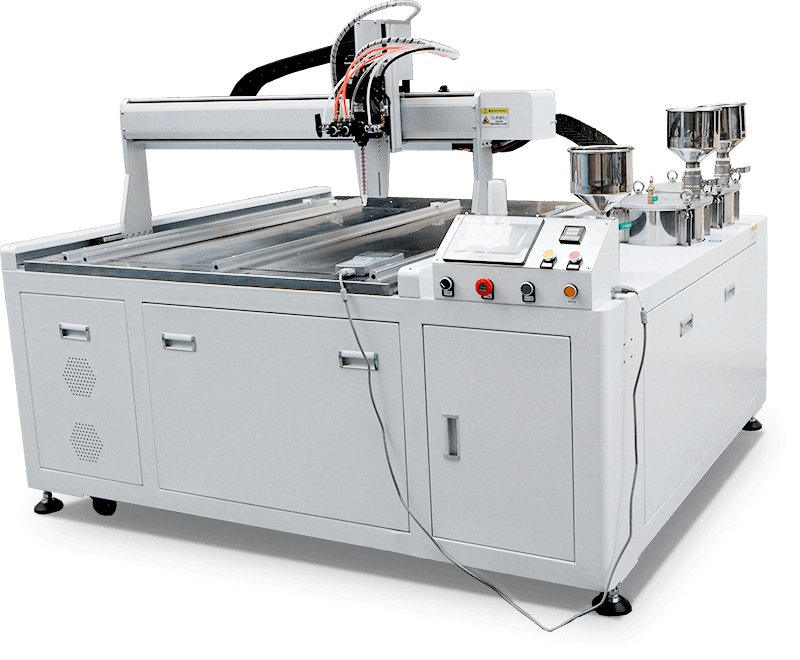

Medium-Scale Solution

Large-Scale Solution