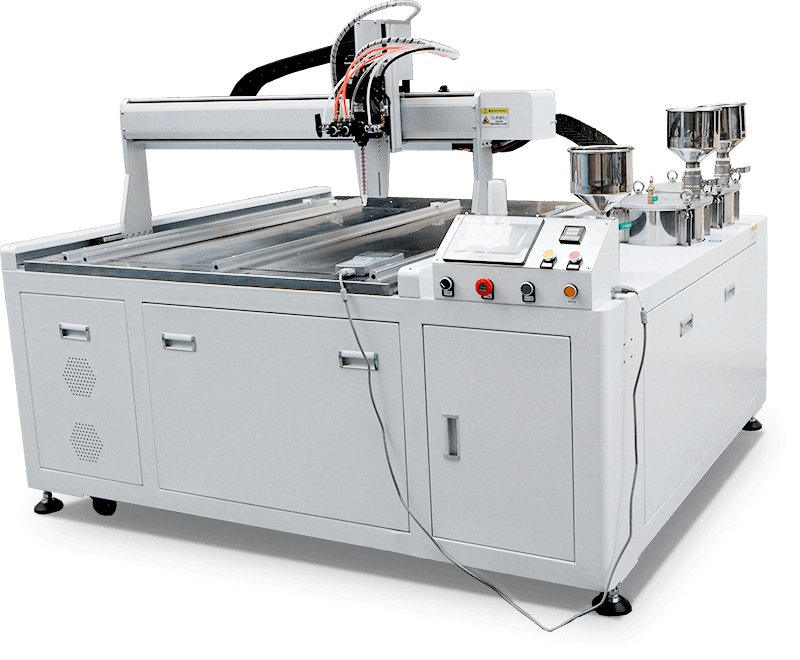

Semi-Auto 3D Sticker Epoxy Resin Doming Machine

Suitable Stickers

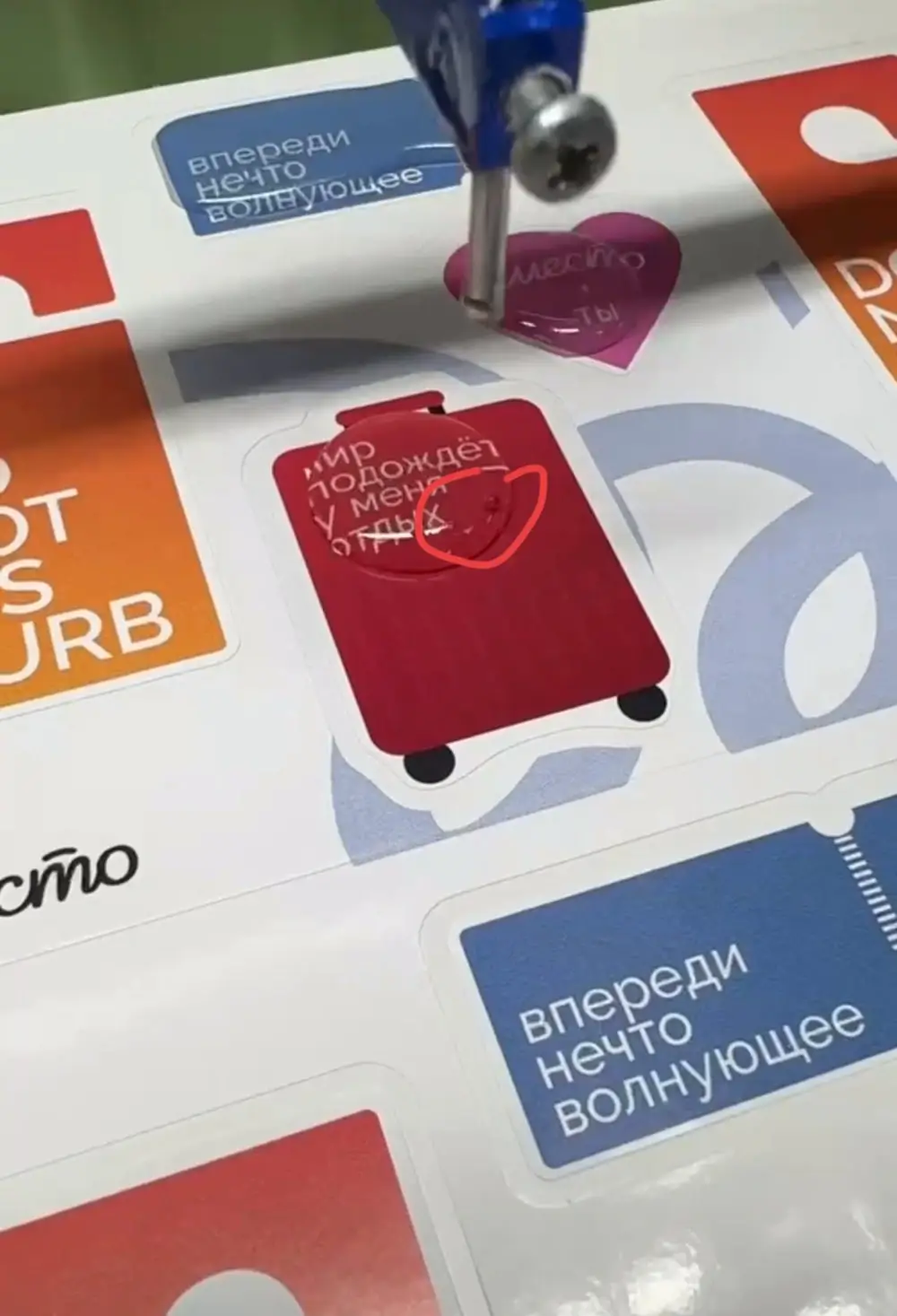

This machine is suitable for all kinds of sticker/label doming.

Latest Projects

Turn Your Challenges Into Real Solutions

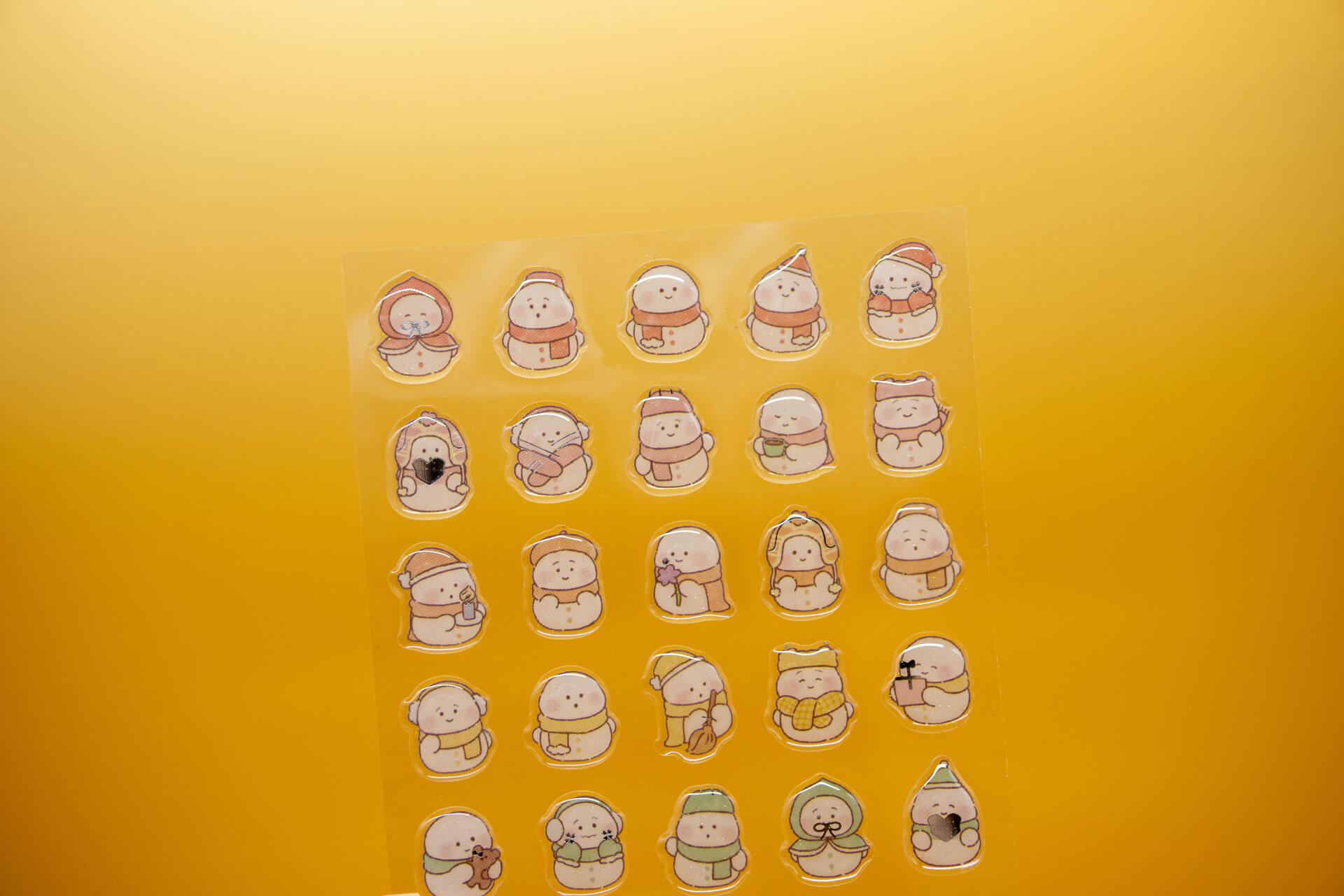

Complex Design Sticker

Tiny PET Toy Sticker

Simple Circle Sticker

Robota

Technical Advantages

What will you get from our doming machine?

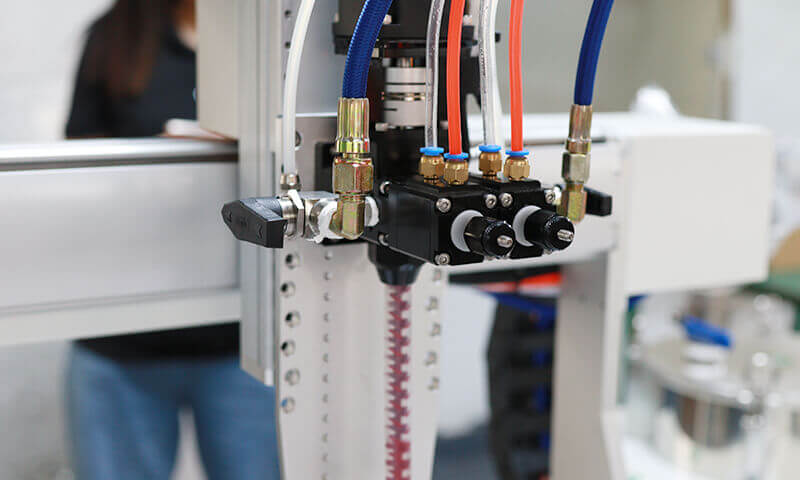

Precision Gear Pump

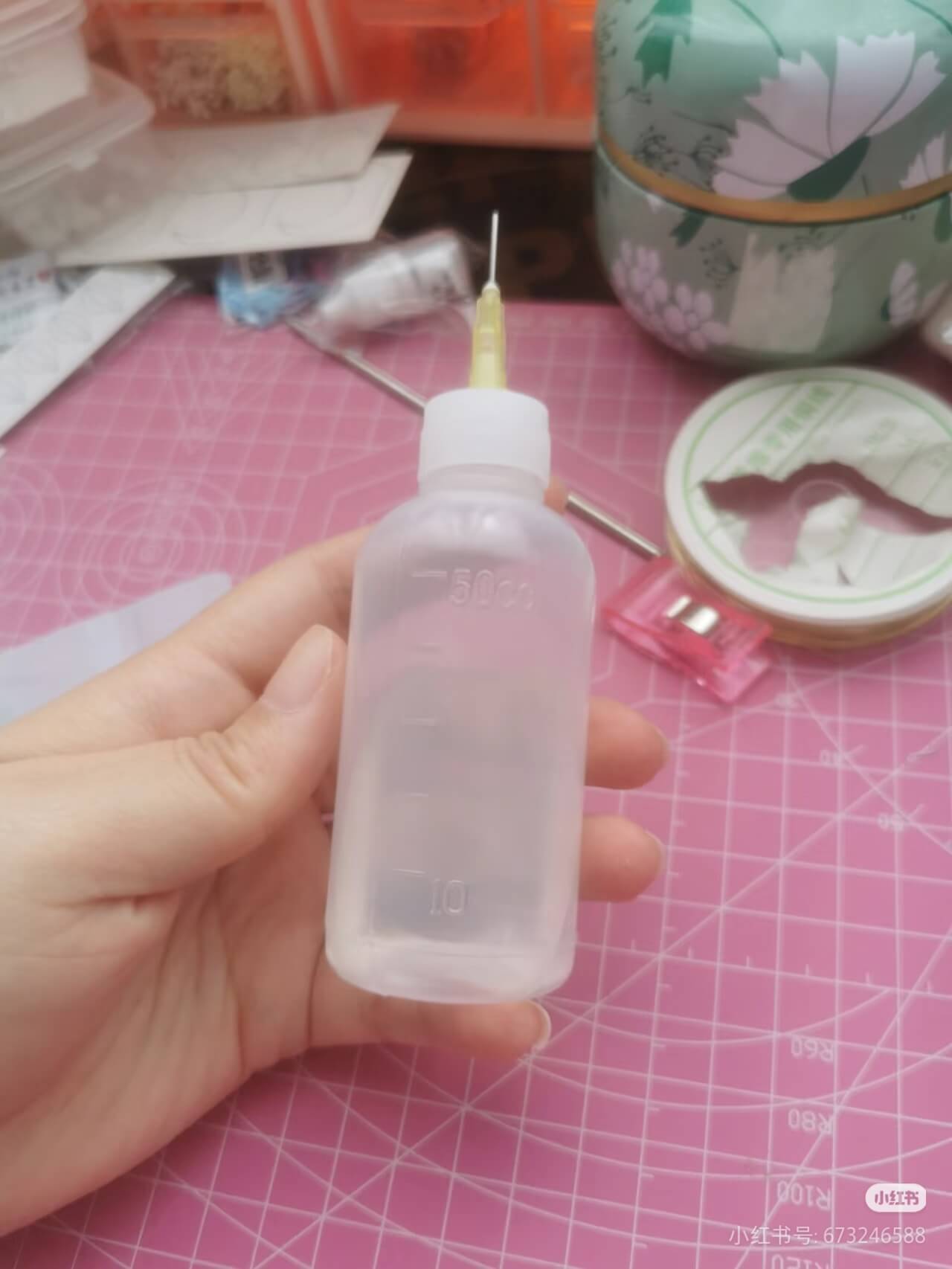

Easy-Use Handheld Nozzle

Dynamic Mixing System

01. Air Bubbles in Stickers

Air trapped during resin dispensing causes visible bubbles, ruining surface clarity and product quality, leading to high rejection rates and rework.

02. Uncured or Sticky Resin

Robota’s engineering team delivers a doming machine specifically optimized for cold environments. The one-button heating system stabilizes resin temperature, ensuring proper curing, consistent hardness, and a flawless glossy finish.

03. Inconsistent Dome Height

Manual dispensing or unstable equipment often produces uneven dome thickness, affecting product uniformity and professional appearance.

04. Slow Production Speed

Manual or semi-automatic processes limit output, making it hard to meet bulk order deadlines and increasing overall production costs.

05. High Material Waste

Inaccurate dispensing and overflow during doming waste expensive resin materials and raise operational expenses.

06. Operator Fatigue & Inaccuracy

Long manual operations lead to operator fatigue, inconsistency, and lower precision, especially for complex or high-volume sticker batches.

Robota

Other Reasons to choose Robota

Spacification

| Specification | Details |

|---|---|

| Glue Mixing Ratio | 1:1-10:1/Customizable |

| Dispensing Speed | 10-150g/5s (based on 1:1 glue proportion) |

| Dispensing Precision | Glue Amount ±1%, Glue Proportion ±1% |

| Pattern | Lines, Points |

| Potting Precision | Amount ±1%, Ratio: ±1% |

| Input Pressure Range | 0.5-0.8MPa |

| Head Sealing Pressure | MAX ≤2.6Mpa |

| Adhesive Viscosity | <10000CPS |

| Operation Method | Manual |

| Control | PLC+Touch Screen (Program setting, modify, save) |

| Leak-proof Function | Adhesive Valve with Suction Control |

| Mixing System | High-speed Dynamic Mixing Device |

| Glue Injecting Control | High Precision Pump |

| Cleaning Tank Volume | 5L (304 Stainless Steel Material) |

| A Glue Tank Volume | 20L (304 Stainless Steel Material) |

| B Glue Tank Volume | 20L (304 Stainless Steel Material) |

| A Pump | High Precision Gear Pump (3.2-12CC) |

| B Pump | High Precision Gear Pump (0.6-2.4CC) |

| A Glue Tank Mixing System | Customize |

| B Glue Tank Mixing System | Customize |

| A Glue Heating System | Support |

| B Glue Heating System | Customize |

| Tank Vacuum Function | Customize |

| Dimension (L*W*H) | 1260*640*1260mm |

| Power Supply | 220V 50Hz 3500W |

Product

What to Consider Before Buying It?

01. Sample Information Collection and Equipment Matching

02. Adhesive Compatibility Check

03. Adhesive Selection Guide

04. Sample Testing

05. Equipment Production and Setup

06. Equipment Delivery and Operational Training

Subscribe for a Free Demo Now

Product

Find The Right Solution

Small-Scale Solution

Medium-Scale Solution

Large-Scale Solution